Collaborative Demand Planning

Collaborative Demand Planning is a combination of rigorous forecasting algorithms to predict future demand, a rich set of ML techniques, including deep neural networks, as well as elaborate collaboration protocols amongst the internal and external stakeholders.

As part of Adexa’s SIOP solutions, collaborative demand planning is the very critical first step of S&OP process and generation of “one forecast” that the entire company can support and depend on to satisfy using the supply capacity and inventory available to the company. Adexa collaborative planning, forecasting and replenishment (CPFR) solution brings speed, accuracy, and simplicity to demand planning; enabling you to increase revenue, organizational agility, and customer service.

Adexa’s Collaborative Demand Planner offers multiple time horizons for analysis of demand and actionable insight. You can perform short term, medium term or long term demand sensing in order to forecast demand as well as analyze capacity planning and even network design. Furthermore, using advanced machine learning techniques the system offers not just the best fit algorithms but also the best policies to be deployed depending on the attributes of products, customers, and regions amongst others. New policies are also mutated by the system in order to enhance the performance of the system even further.

Benefits & Features

- High 90s forecast reliability — even for new products

- Maintain the right inventory levels for demand peaks and valleys

- Simplify promotion planning and cost/benefit analysis

- Analyze profitability by channel, product, and geography and resource requirements

- Maximize spare parts usage and maintenance inventories

- Automated policy selection using neural nets

- Multi-variate analysis

- Seamless integration with Excel for read and write-backs

- Perform replenishment planning

- Multi-tier and see-through forecasting

- Automated algorithm selection using ML with a library of hundreds of algorithms

- Automated policy selection using neural nets

- Multi-variate analysis

- Seamless integration with Excel for read and write-backs

- Perform replenishment planning

- Multi-tier and see-through forecasting

- Automated algorithm selection using ML with a library of hundreds of algorithms

- Short term, medium term and long term demand sensing

Xpress Demand Planning in weeks

Regardless of your size or your business model, your demand planning requirements are just as complicated or critical to your business. you still need to know—accurately and quickly—what your customers would likely to want. You need a solution that ties in timely, accurate, and aggregated demand data from sales, marketing, finance, and customers to create a rich and collaborative view of all demand factors and forecasts.

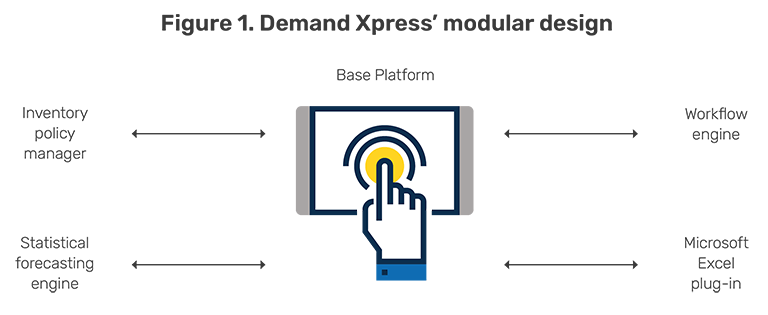

Demand Xpress is an innovative product from Adexa, which provides SMEs with a comprehensive demand planning solution. Demand Xpress offers a full range of demand planning capabilities that can be deployed in a fraction time. This is facilitated through the use of state-of-art ML technology and advanced modular design shown below.

Benefits & Features

- Control procurement in an outsourced manufacturing environment

- Shorten purchasing lead times

- Simplify purchase order tracking

- Optimize sourcing of components and raw materials

- Reduce raw material inventory levels

- Communicate to suppliers in a timely manner

- Create real-time visibility into supplier availability and capacity

- Integrate with existing EDI and messaging backends

Get in touch

Need more information?